Acknowledgements:

We would like to acknowledge and sincerely thank our sponsors for their generous support of our research!

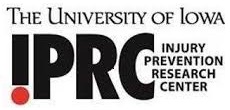

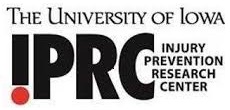

Big Picture:

Selected Projects:

(Last updated: Dec.2016)

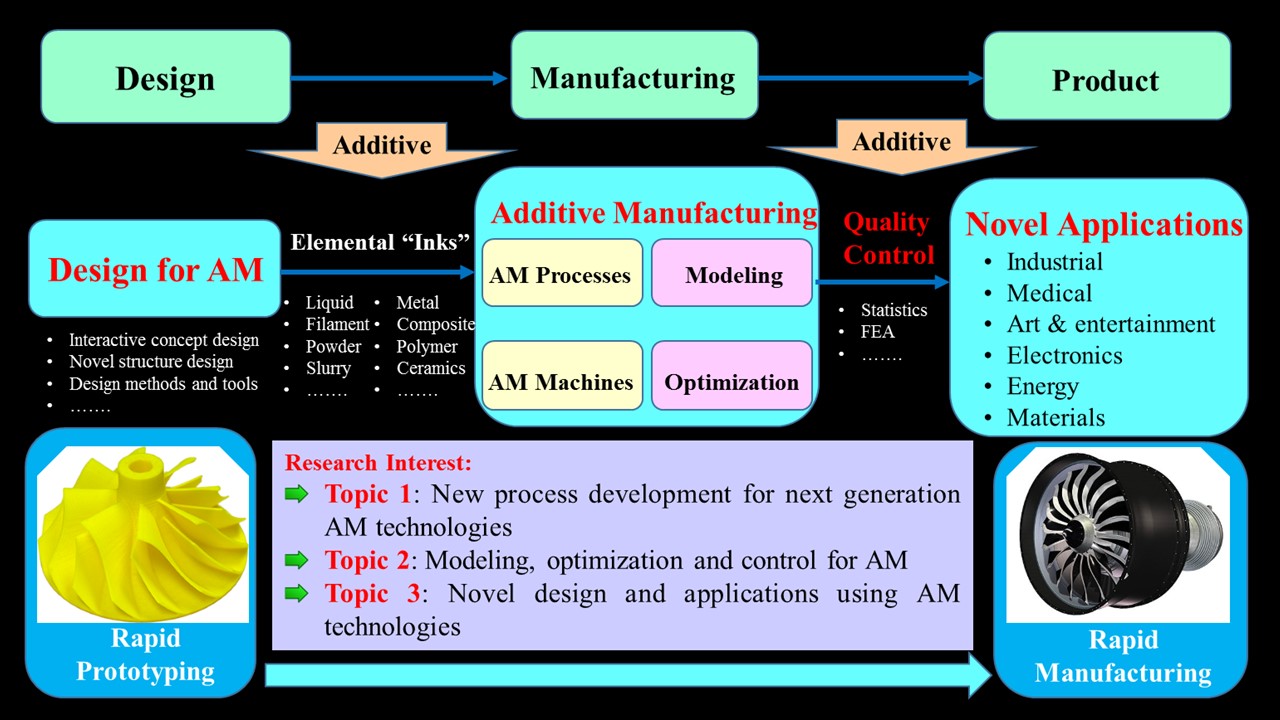

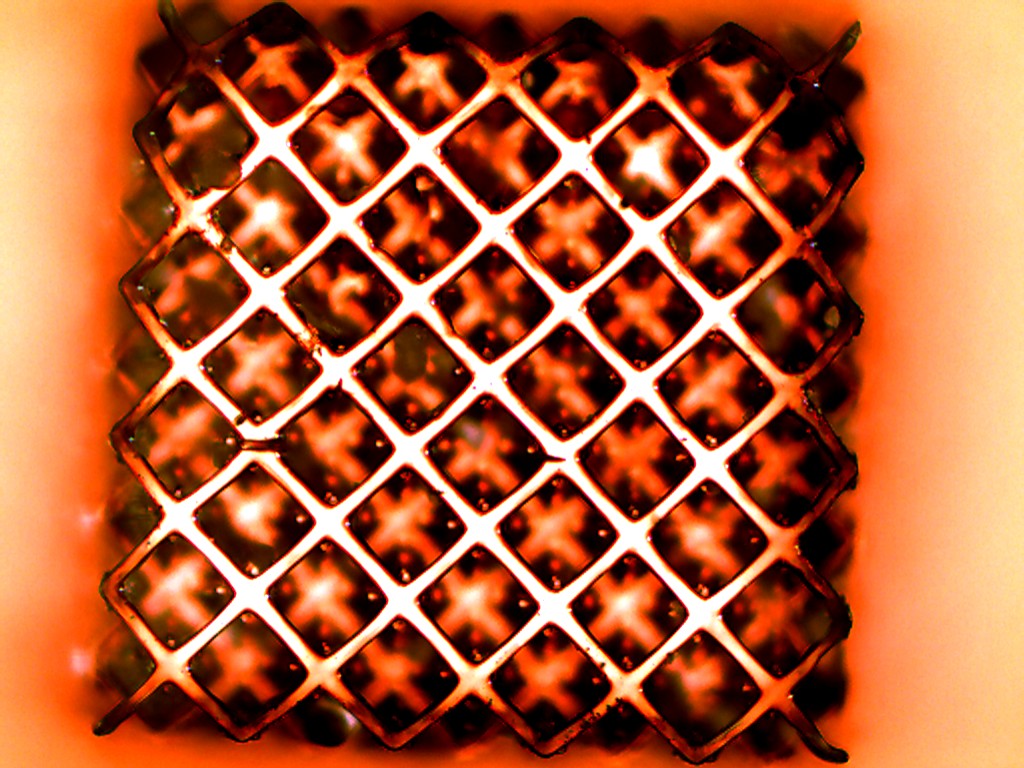

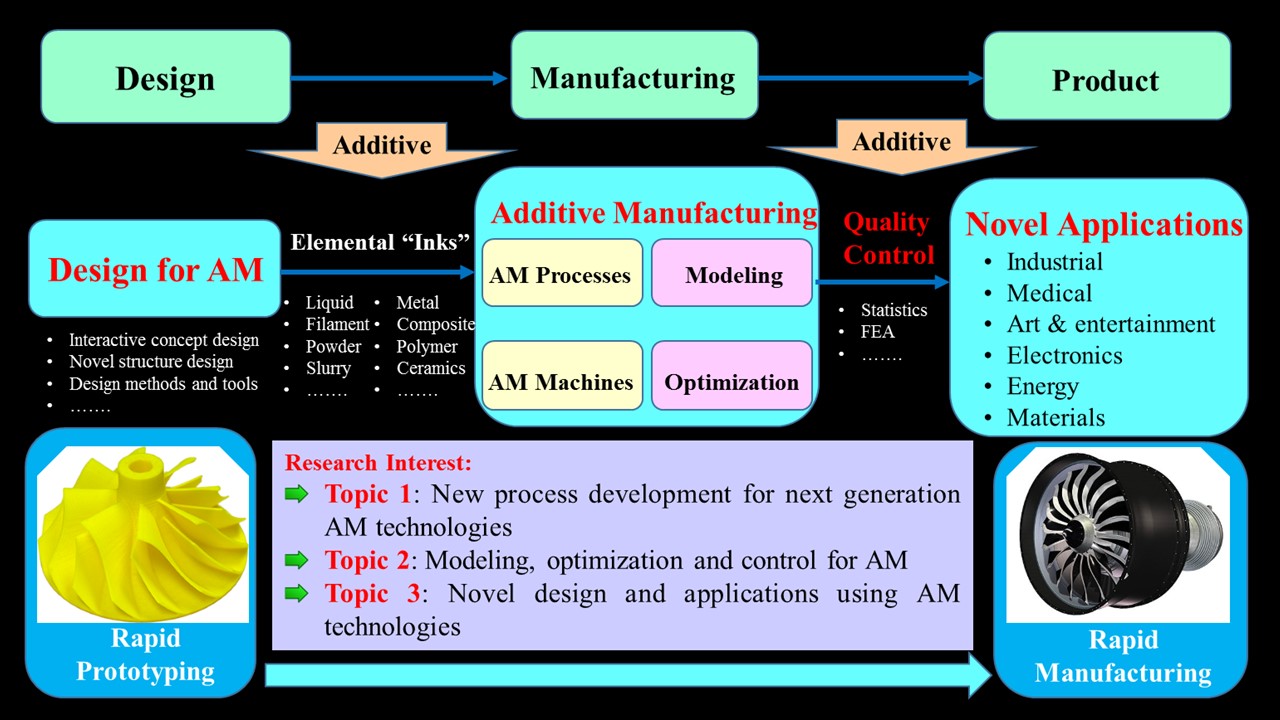

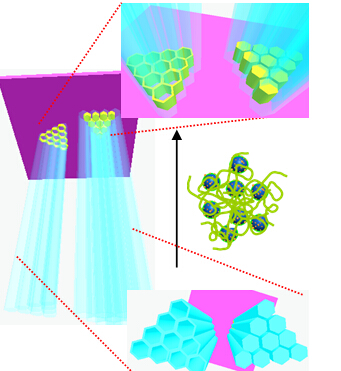

Piezoelectric Device Fabrication Using Digital Projection based Additive Manufacturing.

Developed a novel prototype system to 3d print piezoelectric ceramic devices by integrating tape-casting and stereolithography techniques.

High viscosity (5Pa•s~250Pa•s) and ultra thin layer recoating (less than 10µm) can be achieved in order to fabricate piezoelectric components in sensor, ultrasound transducer, etc.

Use high temperature sintering to burn out organic composition and densify piezoelectric particles.

Developed an image-projection and motion-control integrated software system based on an 8 axis microcontroller (KFlop).

A barium titanate (BTO) based ultrasound transducer array has been made by this process and a d33 of 160 pC/N has been achieved (compared to 190pC/N of bulk BTO). The fabricated piezo-components has been successfully tested in an ultrasound transducer system.

The process has also been used to fabricate calcium phosphate based bone scaffolds, which have been successfully tested and implanted in a rat femur surgery.

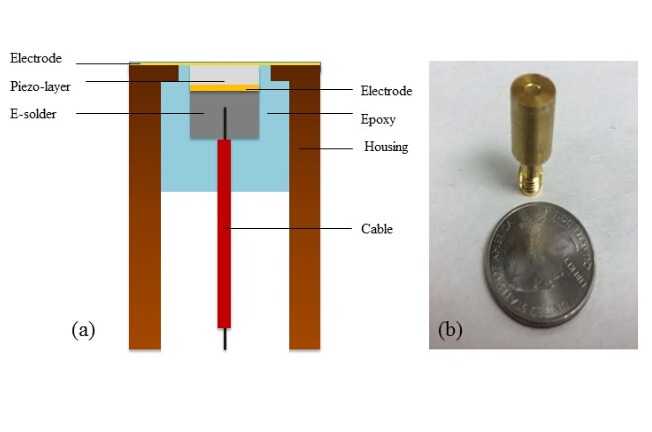

Polymer based Composite Fabrication Using Digital Projection based Additive Manufacturing.

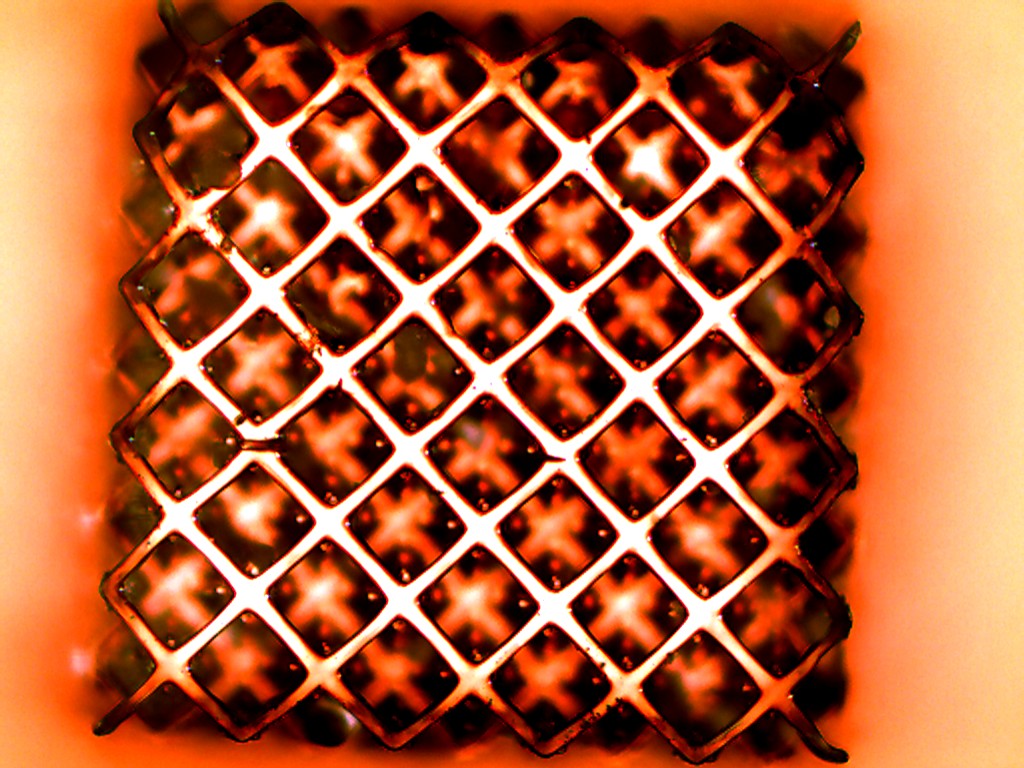

Use 3D Printing process to fabricate microstructures with high dielectric polymer/ceramic composite materials.

Developed a novel fabrication platform to build functionally graded materials with carbon nanotube reinforced composite suspension.

Micro-Scale Fabrication over Large Areas Using Digital Projection based Additive Manufacturing.

Developed a multi-scale stereolithography system, whose smallest feature could be as small as 5µm, and building size could be as big as 50mm.

Use DOE methods to study the effects of light absorber, light intensity and light uniformity on photo-polymerization.

Designed an optical system to adjust the imaging focus and control the quality of fabrication.

Multi-Directional Additive Manufacturing based on Fused Deposition Modeling Process

Developed a low-cost 6 axis parallel kinematic machine for multi-directional additive manufacturing processes based on Fused Deposition Modeling (FDM) process.

Developed a simulation and motion control software system for tool path planning, constraint checking, tool motion simulation and control.

Developed a laser-camera system for 6-axis platform calibration and real-time feedback control of initial deposition gap.

Reported in the media, e.g., Boingboing

and USC’s viterbi school. The machine is selected as a sample case by Dynomotion Inc. in their product instruction.

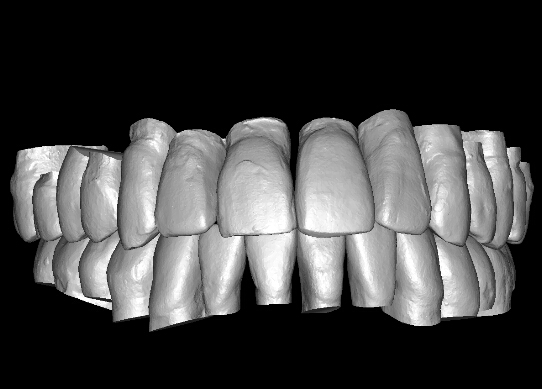

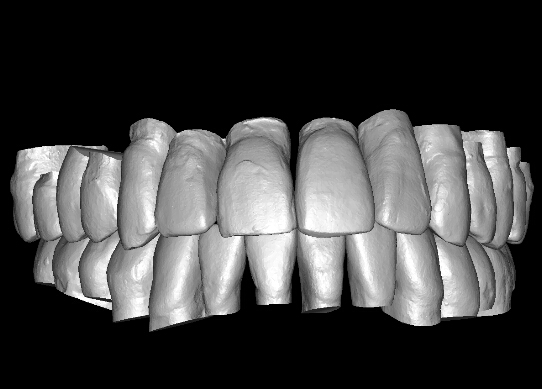

Shape Memory Wire Design for Affordably Priced High-Tech Teeth Braces.

Worked with orthodontists at USC to create a new solution to straighten teeth faster, more comfortably and esthetically. It combines the effectiveness of conventional braces, the aesthetics of behind-the-teeth braces, and the comfort and ease of use of Invisalign all in a single appliance.

Designed shape memory wire contour for teeth samples with CAD software.

2014 USC Maseeh Entrepreneurship Prize Competition (MEPC), the grand prize along with $50K in cash and $20K in legal services for ComfortCorrect.