Return to Main

Return to Research

Return to Main |

Return to Research |

Robotics Research

K.

Abdel-Malek, Department of Mechanical Engineering

H.J. Yeh, Microtek International, Inc., Taiwan

A. Hager, Qualicoat, Inc., NY

L. Adhami, Ecole Superieure en Sciences

Informatiques, Sophia-Antipolis, France

J. Yang, PhD program at the University of Iowa

Research in the

following areas:

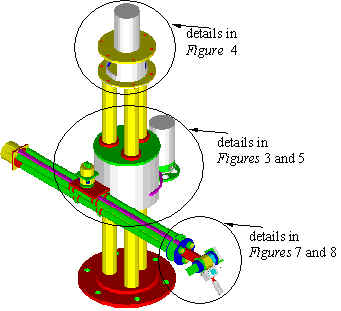

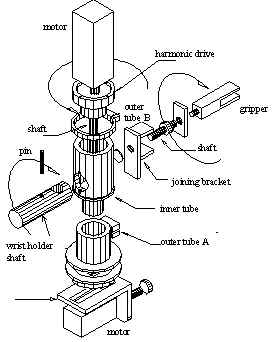

1. Off-Line Simulation and Programming

2. Kinematics and Workspace analysis

3. Design of Robot Manipulators

4. Dexterity and Placement of robot manipulators

See our Publications List by Topic

![]()

1.

Off-Line Simulation and Programming (Based on US Patent

5,511,147)

In a manufacturing environment consisti ng of a multiple

of cells, cell-setup time is often the most costly aspect.

Robotic manipulator arms have been used in the past increase

productivity. Although in many cases, manipulators have reduced

setup times, they do require sophisticated program m ing.

Particularly when the tasks cannot be taught using a teaching

device (e.g. teach pendant). The Objective of the

three-dimensional computer-aided robotics interface (called

3D-CAI) is to provide the robot programmer with a simple

tool to program complex ro b otic functions through interactive

CAD techniques. Representations of the external environment is

constructed using solid modeling techniques. Manipulation of

solids using boolean operators is performed to represent complex

objects. The configuration ( p osition and orientation) of a

triad can be modified by the user. 3D-CAI

provides an off-line programming method where logic, repetitive

tasks, and sensory control can be programmed interactively.

Trajectories are planned by manipulating three-dimensiona l

curves on the screen. Icons are used to represent end-effector

configurations of the manipulator. Linking icons via

three-dimensional curves mandates the motion of the manipulator

arm. The introduction of a graphical environment reduces the task

of vi s ualizing points, orientations, and trajectories rendering

the environment simple to use for non-robotics experts. Two

implementations of this environment are discussed: an

implementation into a sheet-metal manufacturing

cell to reduce setup times, and an implementation into a

workstation for aiding disabled individuals to feed themselfs

through a voice recognition system. Difficulties encountered in

those implementations are discussed. This work is based on US

patent (Abdel-Malek 1995). Subsequent work

included methods for checking and avoiding collisions.

Liu, J.F. and

Abdel-Malek, K., (in press), "Robust Control of

Planar Dual-Arm Cooperative Manipulators", Robotics

and Computer-Integrated Manufacturing

2.

Kinematics and Workspace Analyses

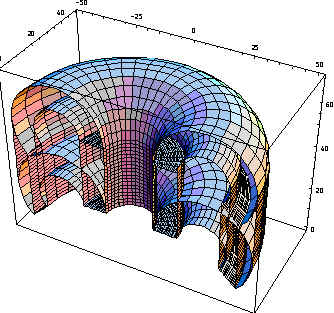

Rigorous mathematical formulations for modeling

and analyzing serial robot manipulators have been

created. Using these formulations, we are able to obtain

closed form solutions of the workspace including barriers

inside the workspace where the manipulator exhibits

control difficulties. Because of this novel approach, we

are able to address issues that were only addressed using

numerical techniques. We have also been able to

demonstrate the workspace envelope (and voids) for many

manipulators. For example, the figures below show the

workspace and internal surfaces (also called in the

literature as singular surfaces).

SEE ALSO A RELATED SITE: THE SWEPT VOLUME COMMUNITY

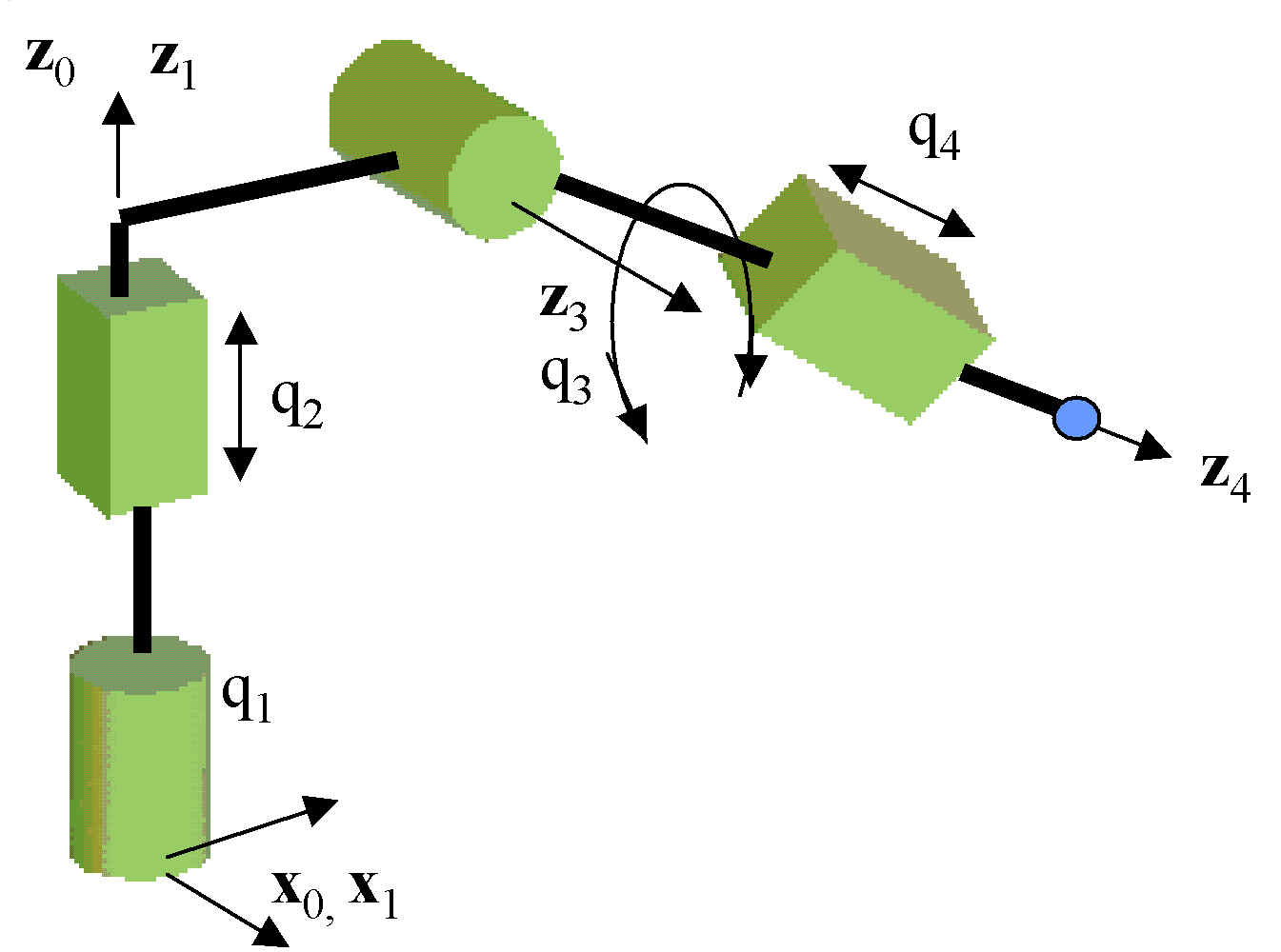

Figure 1 A 4R manipulator Fig. 2 The workspace depicting all singular surfaces

Extension of this work has been implemented to

4.

Dexterity and Placement of Robotics Manipulators

Criteria and implementation for the placement robot

manipulat ors with the objective to reach specified target points

are herein addressed. Placement of a serial manipulator in a

working environment is characterized by defining the position and

orientation of the manipulator\rquote s base with respect to a

fixed reference f rame. The problem has become of importance in

both the medical and manufacturing fields, where a robot arm must

be appropriately placed with respect to targets that cannot be

moved. A broadly applicable numerical formulation is presented.

While other met h ods have used inverse kinematics solutions in

their formulation for defining a locality for the manipulator

base, this type of solution is difficult to implement because of

the inherent complexities in determining al inverse kinematic

solutions. The appro a ch taken in this work is based on

characterizing the placement forcing a cost function to impel the

workspace envelope in terms of surface patches towards the target

points and subject to functionality constraints, but that does

not require the computatio n of inverse kinematics. The

formulation and experimental code are demonstrated using a number

of examples.

Abdel-Malek, K. and Yeh, H. J., (2000) "Local Dexterity Analysis for Open Kinematic Chains," Mechanism and Machine Theory, Vol. 35, pp. 131-154.

Abdel-Malek, K.,

(1996), "Criteria for the Locality of a Manipulator

Arm with Respect to an Operating Point,"IMEChE

Journal of Engineering Manufacture, Vol. 210 (1),

pp. 385-394.