Automatic Computer-Aided

Design of Mechanical Parts

Karim Abdel-Malek, PhD Department Mechanical

Engineering

Jeff Wang, PhD, SDRC, Cincinnati, OH

Hong-Liu Zou, SDRC, Cincinnati, OH

Saib Othman, PhD, NADS,

Oakdale, IA

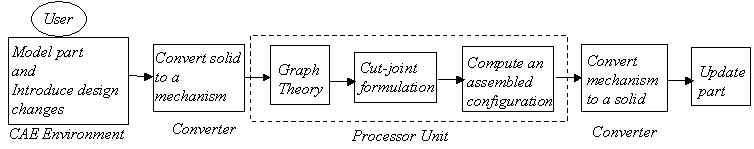

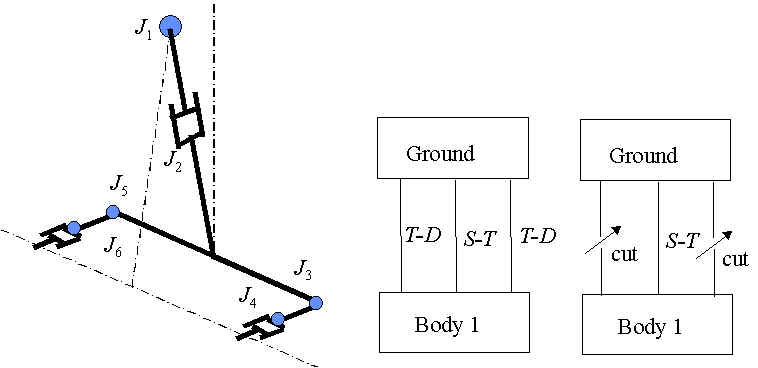

| This research is aimed at developing intelligent

methods for the automatic design of parts modeled in a

computer aided design (CAD) system. A complete plan based

on a rigorous mathematical formulation to achieve this

goal is presented. In this work, computer models of solid

objects are modeled as links and joints to form an

assembly. The assembly is represented using graph theory

to obtain a clear exact representation. The method of cut-joint kinematic constraint, recently developed by the PI and colleagues, is used to compute an assembled configuration of the mechanism given a design variation. A change in the design of the part, whether in dimension or shape, will cause the formulation to update the part such that the mechanism is still functional. Once a kinematically admissible design is computed, the part is updated such that a new design is obtained. The ultimate goal is to completely automate the redesign process in CAD systems thus reducing lead times and manufacturing costs. |

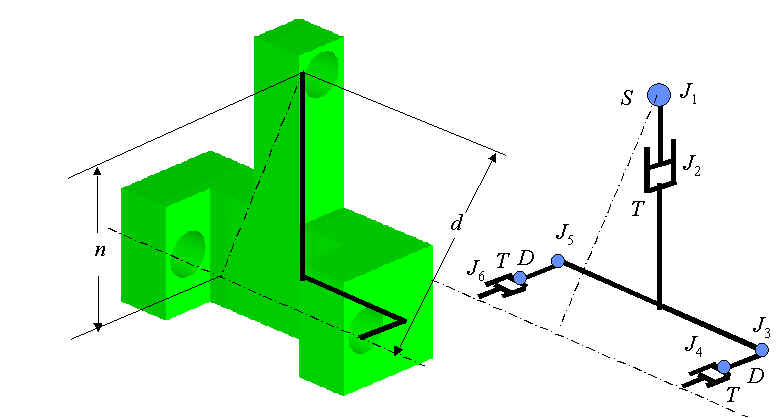

A mechanical part is automatiocally converted into a mechanism. Kinematic relations are used to define the relations between joints and links.

Graph theory is used to model the mechanism (and hence the mechanical part).

A design variation is introduced and an assembled mechanism is computed. The part is updated (redesigned). This method presents a powerful formulation for inherent automated CAD systems.